Year

2025 (3 weeks)

Client

Project

B2B SaaS - Concept Design

Batch traceability

Role

Product Designer

Team

Squizify

Food Safety

When someone gets sick, every minute counts

How can we redesign batch traceability in Squizify to turn recalls from painfully slow to seamlessly fast?

Overview

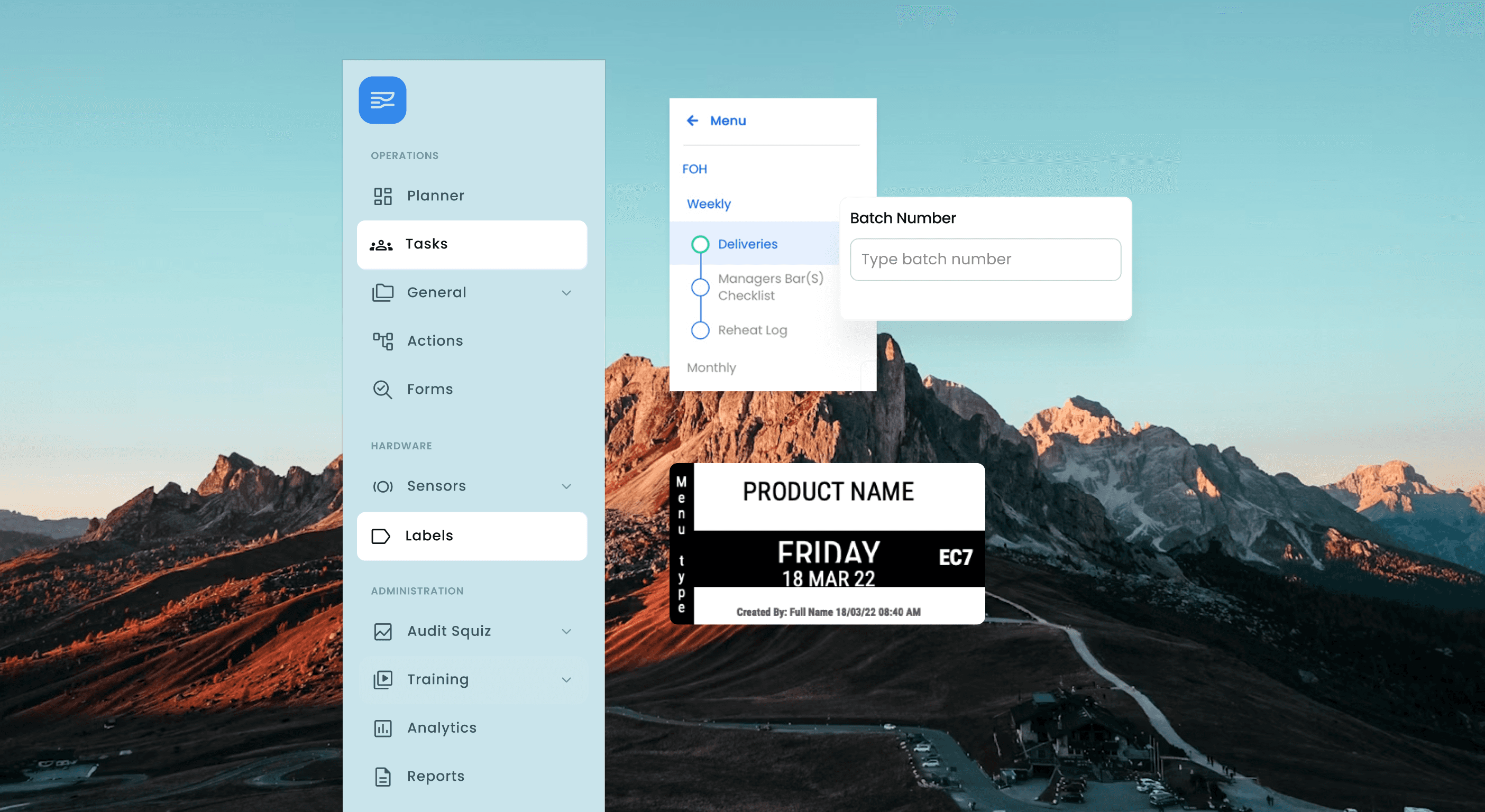

Batch traceability enables food safety teams to track products through every stage of the supply chain, from ingredient sourcing to handling, which is critical for rapid recalls and regulatory compliance

This project was a concept design for improving batch traceability in the Squizify app, laying the foundation for end-to-end supply chain traceability in the future and serving as a nice-to-have to win a potential client.

I co-planned and co-facilitated the ideation workshop, iterated and delivered the design.

Impact

Labels and deliveries didn't talk

Imagine a customer gets sick after eating a burger. The clock starts ticking. Teams race to trace the contaminated food backwards: plate → batch → delivery → handling. But the trail? Broken, manual, painfully slow.

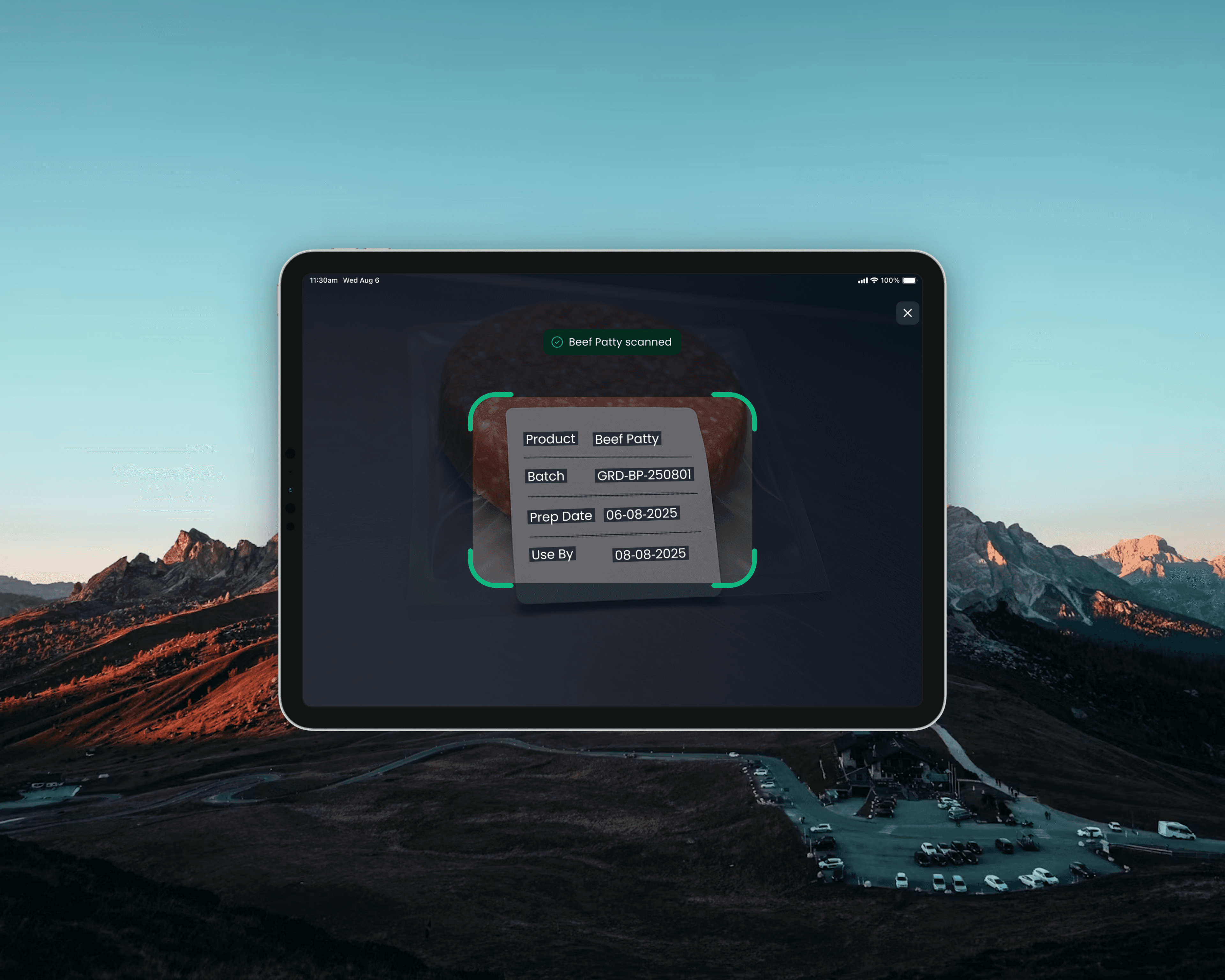

Batch numbers were typed by hand, allowing human errors to creep in. Labels were printed separately, disconnected from the batches they represented. Reporting showed counts, not stories. A burger's journey ended in mystery, not visibility. In food safety, minutes matter. We needed to make those minutes count.

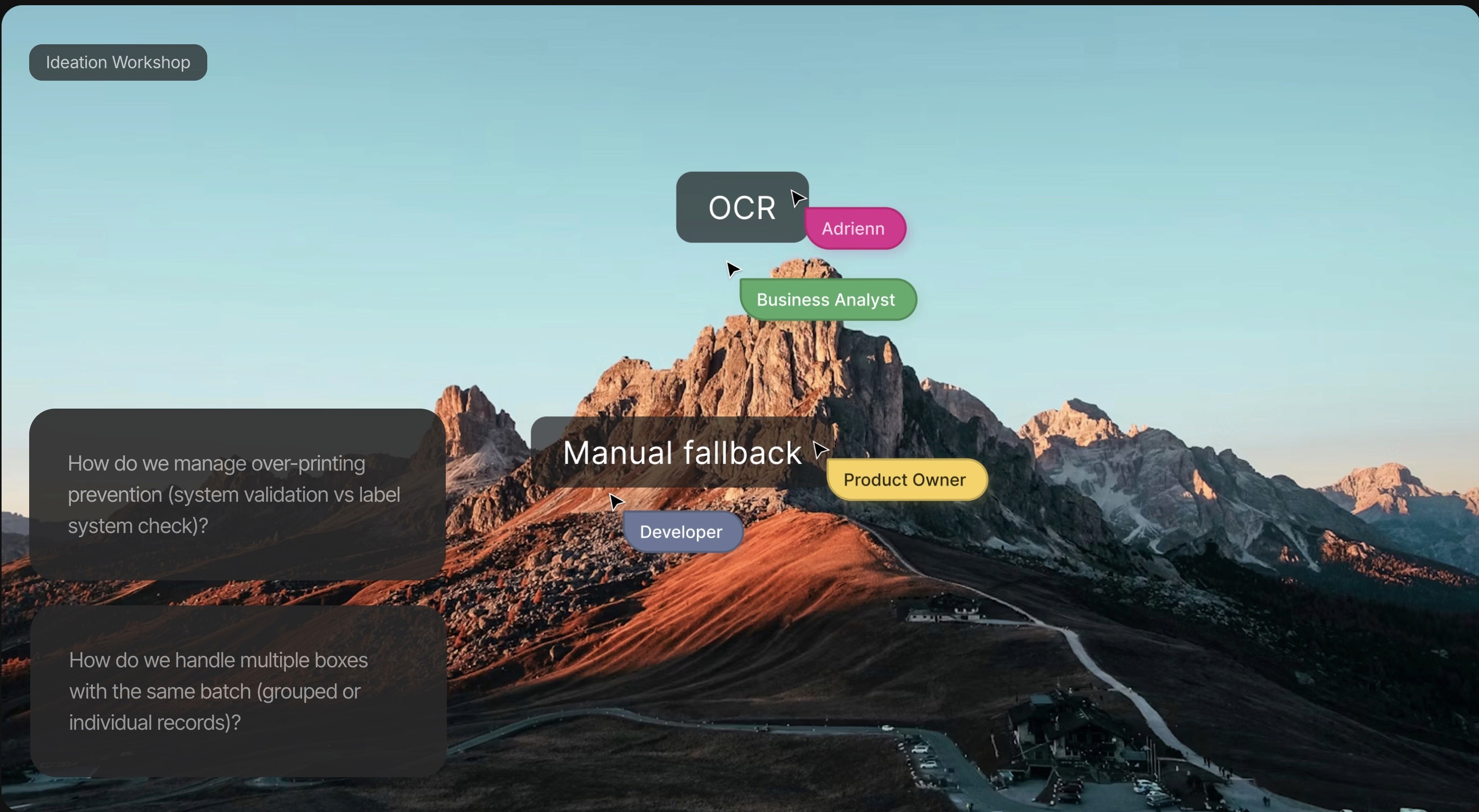

Questions sparked a collaborative ideation session

How could we connect labels and deliveries into one seamless flow, with technical limitations and a tight timeline? We sat down with SMEs to understand how batch traceability worked in Squizify. We also looked at what big retail companies were doing. OCR (Optical Character Recognition) kept coming up, a potential solution that could eliminate manual entry and reduce errors. We mapped out the task flow for new delivery, sticky notes covering the walls as we worked through each step with the team. OCR with a manual fallback? Agreement. Now we had a direction.

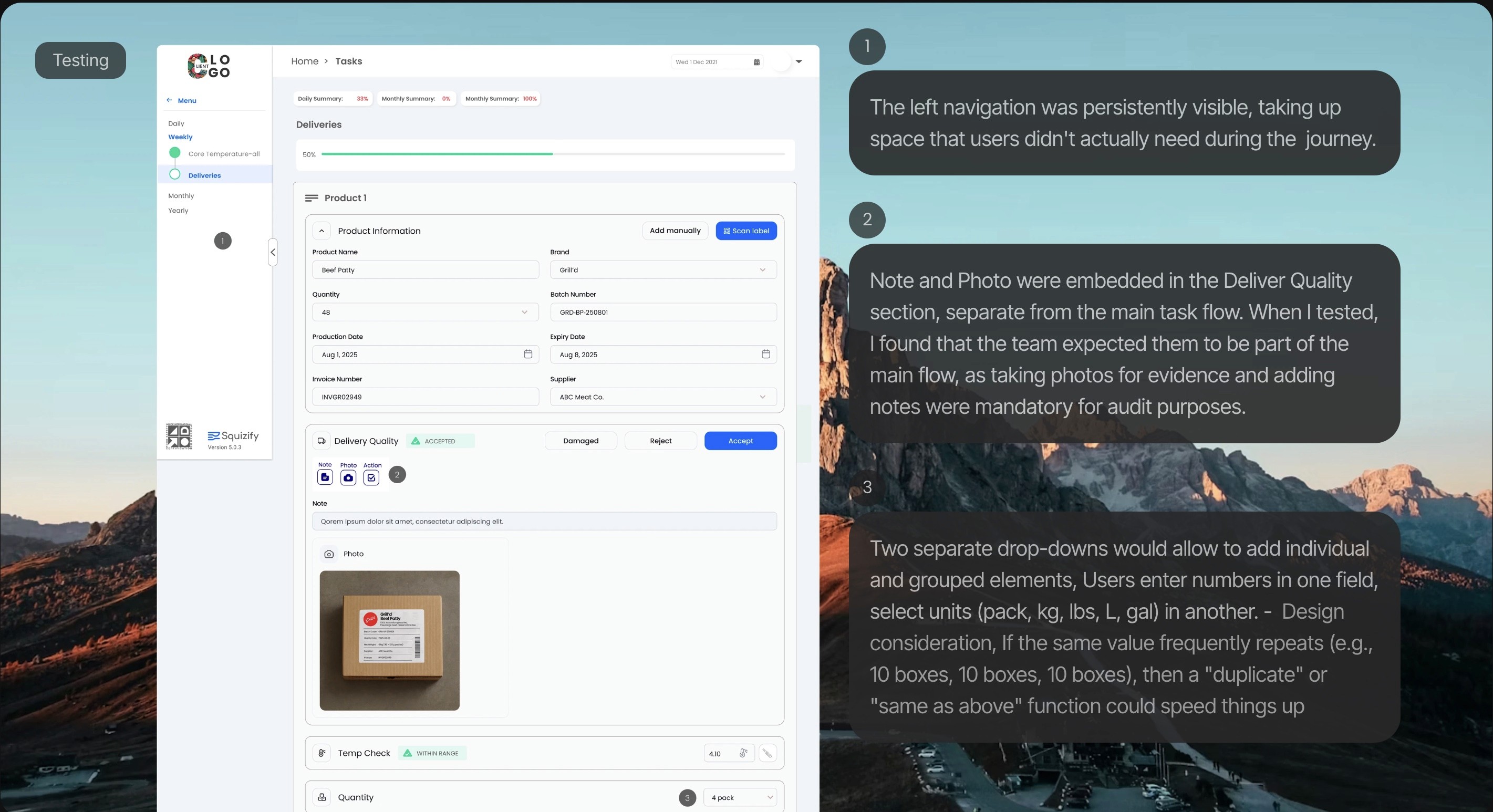

Design sprint to deliver the concept on time

I designed, iterated, and refined based on team feedback. The constraint? Squizify's existing components, no custom elements. I had to work fast and reuse what we had while keeping it intuitive.

Positive client feedback

The result? Manual typing replaced with OCR scanning. Processing time slashed. Client feedback confirmed we'd created something that could save those critical minutes.

What could be?

But what if we weren't constrained? This is a concept with a completely new design system, unconstrained. A glimpse of what batch traceability could become.